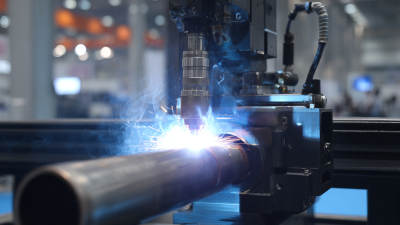

In the competitive landscape of manufacturing and production, precision and efficiency are paramount, particularly when it comes to the optimal functioning of Spray Machine Parts. These components play a critical role in the performance of any spraying system, affecting everything from the application quality to the overall output efficiency. As industries strive for better performance and sustainability, understanding the importance of maintaining and optimizing spray machine parts has become essential. This guide delves into the best practices for enhancing the performance of these vital components, exploring innovative solutions and techniques that can lead to substantial improvements in operational efficacy. Whether you are a seasoned professional or new to the field, unlocking the potential of your spray machine parts can significantly impact your productivity and profitability.

To maximize spray efficiency in your operations, it's essential to track several key performance metrics that directly influence the overall functionality of your spray machine parts. First and foremost, monitoring flow rate is crucial. A consistent flow rate ensures an even distribution of materials, preventing over-spraying and under-spraying scenarios.

Deviations from the ideal flow can lead to wasted resources and compromised product quality, making it a critical metric that should be regularly reviewed.

To maximize spray efficiency in your operations, it's essential to track several key performance metrics that directly influence the overall functionality of your spray machine parts. First and foremost, monitoring flow rate is crucial. A consistent flow rate ensures an even distribution of materials, preventing over-spraying and under-spraying scenarios.

Deviations from the ideal flow can lead to wasted resources and compromised product quality, making it a critical metric that should be regularly reviewed.

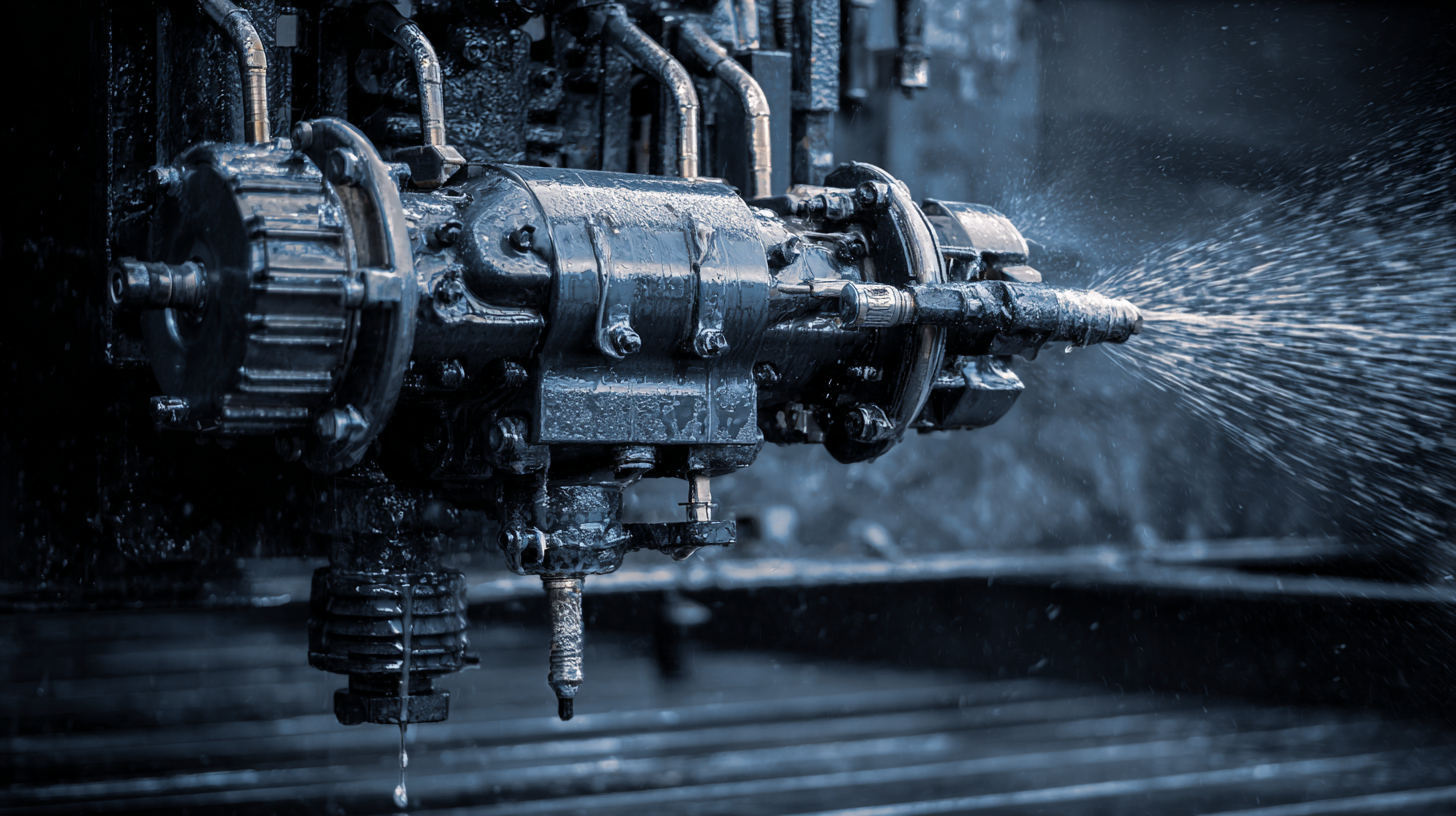

Another vital parameter is the spray pattern uniformity. By conducting tests that assess both the shape and size of the spray pattern, operators can identify issues related to nozzle wear or clogging. This information allows for timely maintenance and adjustments to be made, ensuring that the machine operates at its highest efficiency. Additionally, tracking the nozzle pressure can provide insights into the overall performance of the spray machine.

Proper pressure levels not only assist in achieving the desired spray quality but also extend the life of the nozzles, reducing downtime and maintenance costs. By prioritizing these performance metrics, you can unlock significant improvements in the efficacy of your spray applications.

When it comes to optimizing spray machine components, it's crucial to evaluate several key performance indicators.

One of the foremost indicators is the flow rate, which determines how efficiently the machine delivers the spray material. A consistent and adequate flow rate ensures uniform coverage, reducing waste and boosting productivity. Monitoring this metric regularly can prevent downtime and costly interruptions in the production process.

Another important indicator is the pressure consistency. Fluctuations in pressure can lead to inconsistent spray patterns, affecting both the quality of application and the overall efficiency of operations. Regularly checking and calibrating pressure can significantly enhance the machine's performance. Additionally, the wear and tear of the nozzle should be closely observed, as degraded nozzles can compromise both the precision and quality of the spray.

By focusing on these indicators—flow rate, pressure consistency, and nozzle condition—operators can make informed decisions that enhance the lifespan and functionality of their spray machines.

Wear and tear on spray machine parts can significantly impact the quality of the output, leading to inefficiencies and increased costs. As components experience degradation over time, the precision of spray patterns diminishes, often resulting in uneven application and increased overspray. Statistically, it has been shown that even a slight decrease in nozzle performance can lead to up to a 15% increase in material wastage, which not only affects the overall efficiency but also the final product quality.

Understanding the specific areas where wear occurs is crucial for maintaining optimal spray performance. Research indicates that regular maintenance and timely replacement of worn parts can enhance spray quality by up to 20%. For instance, monitoring the condition of nozzles and pumps can prevent these common failure points from becoming detrimental to production processes. By analyzing wear and implementing proactive maintenance strategies, operators can maintain consistent quality while significantly reducing operational costs.

To extend the lifespan of spray machine parts, regular maintenance is essential. Begin by establishing a routine cleaning schedule. After each use, wipe down all surfaces and components to remove paint, residue, or any chemicals that may cause corrosion over time. Pay special attention to the spray nozzle and filter, as these parts are prone to clogging. A clean machine not only operates more efficiently but also reduces the likelihood of costly repairs.

Another critical aspect of maintenance is lubrication. Ensure that all moving parts are properly lubricated according to the manufacturer's specifications. This will minimize friction and wear, leading to a smoother operation and a longer lifespan for your equipment. Additionally, regularly checking for any signs of wear or damage can help you address potential issues before they escalate. By implementing these essential maintenance tips, you can significantly enhance the performance and durability of your spray machine parts.

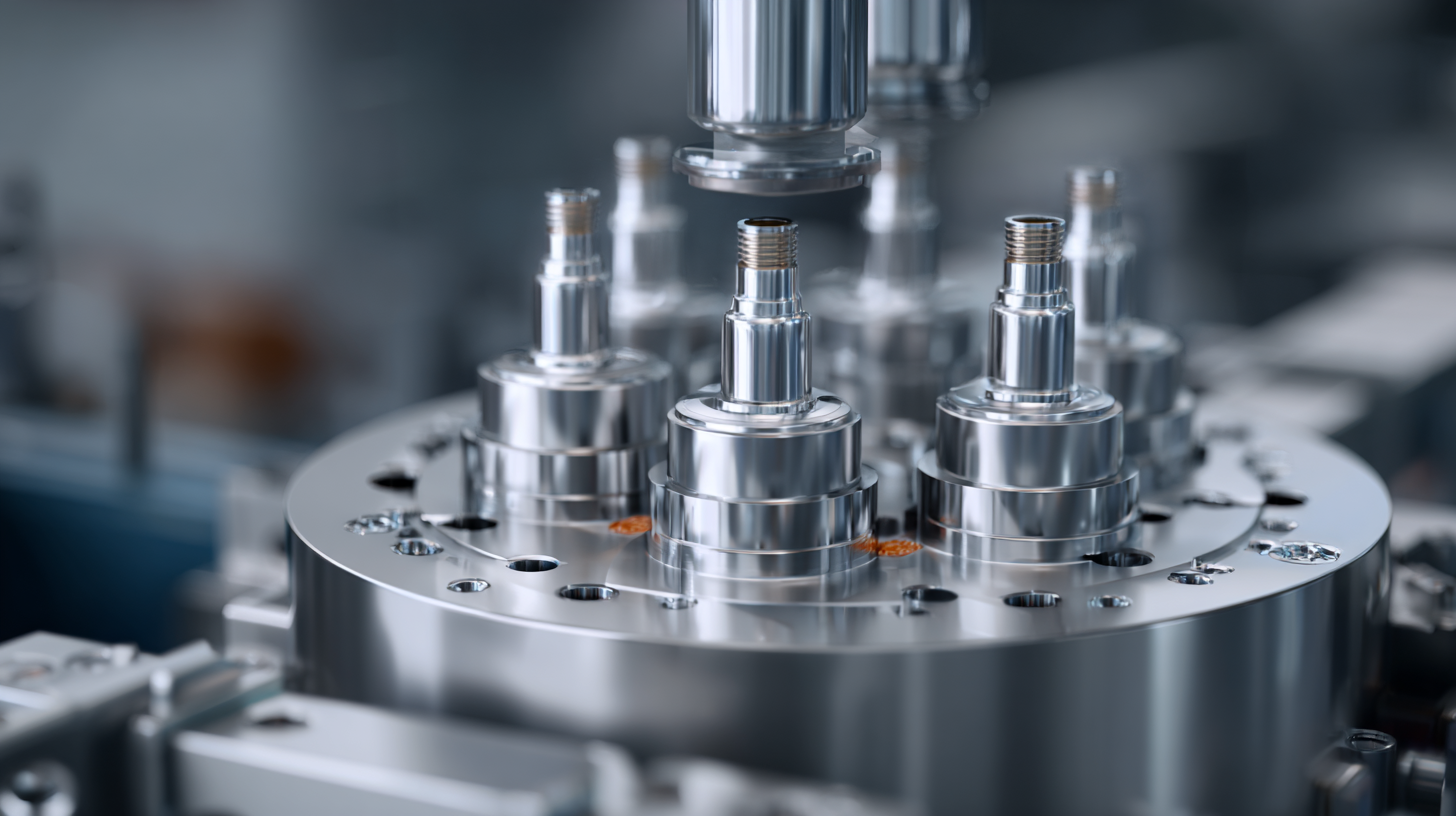

In the ever-evolving landscape of spray technology, innovations and upgrades are paramount for enhancing application efficiency. According to a report by MarketsandMarkets, the global market for industrial spray equipment is projected to reach $8.2 billion by 2025, driven by advancements in spray technology that increase precision and reduce waste. Incorporating newer components such as high-efficiency nozzles and automated control systems can significantly optimize performance, with studies showing that these upgrades can cut material consumption by up to 30%.

Furthermore, innovations in smart technologies, such as IoT-enabled spray machines, are transforming how industries approach maintenance and operation. A survey conducted by the Spray Equipment Manufacturers Association (SEMA) found that organizations using advanced predictive maintenance systems reported a 20% increase in operational efficiency. These enhancements not only streamline application processes but also contribute to sustainability goals by minimizing environmental impact through reduced over-spraying and improved material usage. As such, investing in modernized spray machine parts is critical for businesses aiming to stay competitive and efficient in today's market.