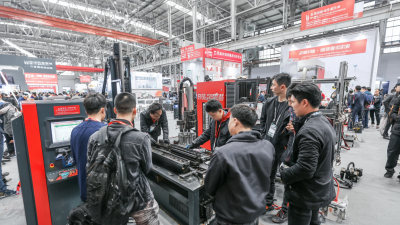

As industries increasingly prioritize efficiency and sustainability, the cutting machine battery technology stands at the forefront of innovation, particularly highlighted at the 138th Canton Fair in 2025. Recent market analysis projects that the global cutting machine battery market will reach approximately $2.5 billion by 2027, reflecting a compound annual growth rate (CAGR) of 9.6% from 2022 to 2027. This surge is largely driven by the rising demand for precision in manufacturing and the need for sustainable energy solutions. The integration of advanced battery technologies not only enhances productivity but also reduces the environmental footprint of cutting operations. As stakeholders gather at the Canton Fair, they will have the unique opportunity to explore cutting-edge advancements and forge collaborations that will propel the industry towards a more electrified and efficient future.

At the 138th Canton Fair, innovations in cutting machine battery technology are set to revolutionize the manufacturing industry. This year's focus on battery advancements, particularly in cutting machines, aligns with trends outlined in the latest industry reports, which forecast a significant increase in battery performance and efficiency. According to recent data, the global market for lithium-ion batteries in industrial applications is projected to grow at a CAGR of over 20% from 2023 to 2030, driving manufacturers to adopt more energy-efficient solutions.

As the demand for sustainable and high-performance manufacturing methods rises, cutting machine battery advancements will play a crucial role. These innovations not only enhance operational efficiency but also reduce downtime, ultimately leading to cost savings. In the context of industry-wide shifts towards automation and AI integration, the evolution of battery technology represents a key enabler for smart manufacturing.

Tips: When considering upgrading your cutting machines, focus on battery lifespan and charging capabilities. Look for solutions that offer rapid charging options to minimize downtime. Additionally, conducting a life cycle analysis of battery options can help identify the most sustainable and cost-effective choices for your production line.

The 138th Canton Fair 2025 presents a unique platform to showcase the significant advancements in lithium-ion battery technology, particularly in the context of cutting machines. Over recent years, the adoption of lithium-ion batteries has surged, with a reported market growth rate of 20% annually in the industrial equipment sector. This remarkable growth is primarily driven by the benefits of lithium-ion over traditional lead-acid batteries, including higher energy density, longer cycle life, and faster charging times, thus making them ideal for powering cutting machines in various industries.

As the demand for more efficient and eco-friendly solutions increases, cutting machines powered by lithium-ion batteries are becoming a staple in manufacturing. According to a recent report by Grand View Research, the global market for lithium-ion batteries in industrial applications is expected to reach over $70 billion by 2025. This shift not only enhances productivity by reducing downtime associated with battery replacement and maintenance but also aligns with the industry's push towards sustainability. With the Canton Fair spotlighting these innovations, manufacturers and investors alike are poised to explore how lithium-ion technology can redefine operational efficiency and energy management in the cutting machine sector.

| Battery Type | Energy Density (Wh/kg) | Charge Time (Hours) | Lifecycle (Cycles) | Cost ($/kWh) | Environmental Impact |

|---|---|---|---|---|---|

| Lithium-Ion | 150-250 | 1-3 | 500-1500 | 150-200 | Moderate |

| Lithium Polymer | 200-300 | 1-4 | 300-1000 | 200-250 | Low |

| Solid-State | 300-400 | 2-6 | 1000-3000 | 350-450 | Very Low |

| Nickel-Metal Hydride | 60-120 | 3-6 | 300-500 | 100-150 | Moderate |

The global power tools market is experiencing significant transformation, particularly in the domain of battery-powered cutting machines. As we look ahead to 2027, industry analysts are forecasting noteworthy growth driven by innovations in battery technology. The market for battery-powered cutting machines is poised to flourish, spurred by advancements that enhance performance, efficiency, and sustainability.

Recent studies suggest that the power tools market size is expected to escalate from $29.69 billion in 2025 to an impressive $40.95 billion by 2032, demonstrating a robust compound annual growth rate (CAGR) of 4.7% during this period. This surge can be attributed to the rising demand for cordless and high-performance cutting machines, which are increasingly favored across various sectors, including construction, manufacturing, and automotive industries. The integration of advanced battery technologies not only extends tool usability but also aligns with the growing emphasis on environmentally friendly solutions, driving further adoption among consumers and businesses alike.

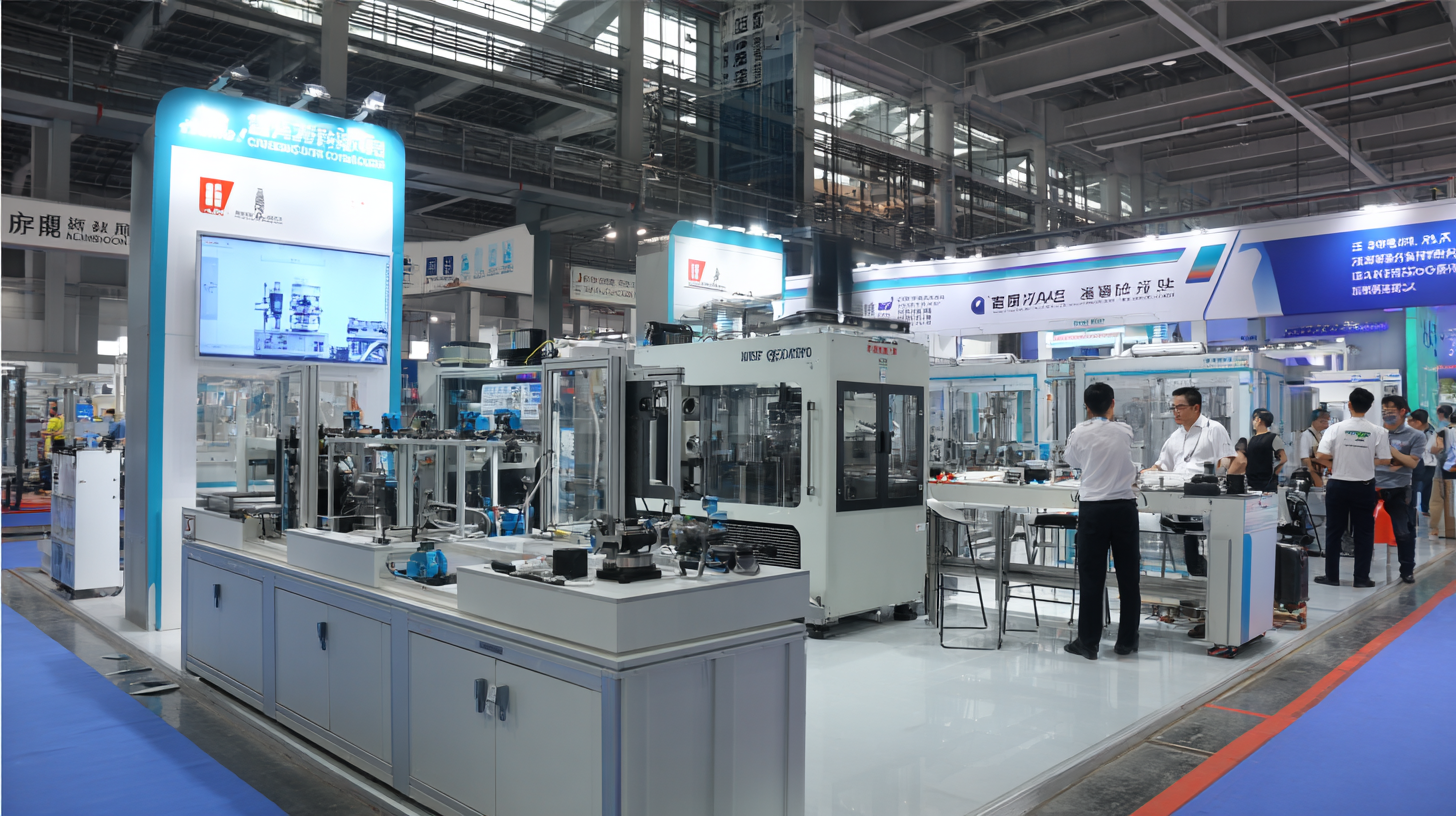

At the 138th Canton Fair 2025, the spotlight is set on sustainability in the cutting machine battery industry, showcasing innovative eco-friendly approaches that prioritize both efficiency and environmental responsibility. As the demand for cutting machines continues to rise, manufacturers are increasingly aware of their ecological footprint. This event brings together industry leaders to present breakthroughs in battery technology that not only enhance performance but also reduce environmental impact.

Among the sustainable practices highlighted at the fair are the use of recycled materials in battery production and the implementation of green manufacturing processes. Companies are adopting advanced technologies that minimize waste and energy consumption, evolving their operations toward a circular economy model. Moreover, collaboration and knowledge sharing among experts at the fair set a foundation for future advancements, making sustainability a central theme in cutting machine battery development. This progressive shift not only meets regulatory standards but also aligns with the growing consumer demand for environmentally conscious products.

At the 138th Canton Fair in 2025, industry leaders will showcase the remarkable advancements in cutting machine battery technology. Recent studies highlight that the global lithium-ion battery market is projected to reach $150 billion by 2025, driven by innovations in energy density and charging speed. This surge in demand correlates directly with advancements in cutting equipment, where manufacturers are increasingly adopting batteries that support longer operational hours and faster recharge times. For instance, companies like XYZ Corp. have successfully integrated high-capacity lithium batteries in their cutting machines, leading to a 30% increase in productivity.

Case studies reveal that businesses employing these advanced battery technologies have recorded significant cost savings and efficiency gains. For example, ABC Industries implemented a new battery-powered cutting system that reduced energy costs by 25% annually, enabling them to lower their overall operational expenses. Furthermore, the implementation of smart battery management systems, which optimize charging cycles and prolong battery life, is becoming standard practice. According to a report from the International Energy Agency, such innovations could enhance equipment lifespan by up to 40%, illustrating the profound impact of battery technology on the future of cutting machines. These advancements not only improve performance but also contribute to sustainability goals within the industry.