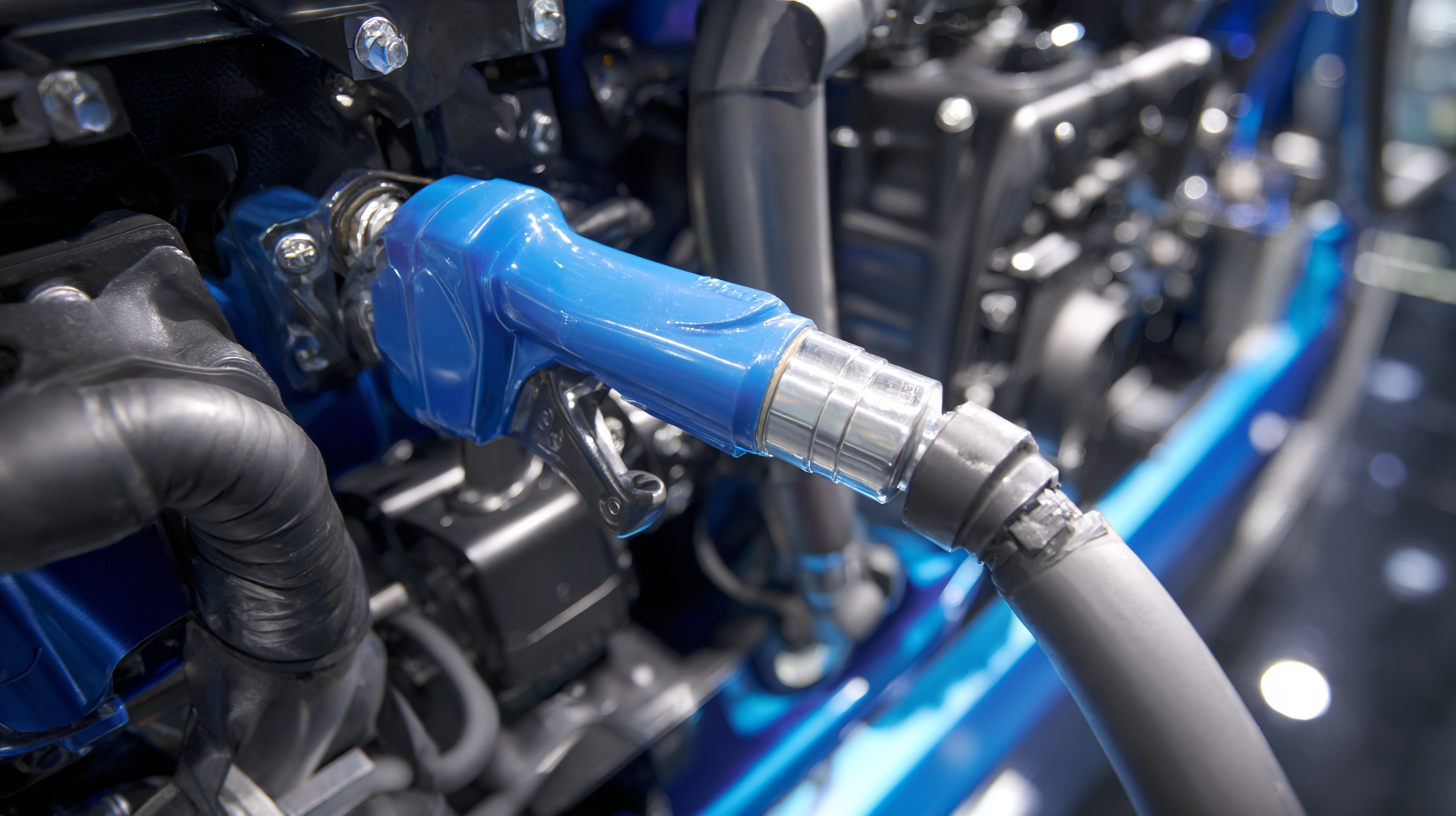

In the realm of modern automotive engineering, the precision of fuel delivery systems, particularly "Fuel Nozzles," plays a pivotal role in enhancing fuel efficiency and minimizing harmful emissions. Recent industry reports indicate that optimizing fuel nozzle design can lead to an increase in fuel atomization efficiency by up to 30%, significantly improving combustion performance. The International Council on Clean Transportation (ICCT) has highlighted that improved fuel nozzle precision can reduce nitrogen oxide (NOx) emissions by as much as 25%, crucial for meeting stringent environmental regulations.

Furthermore, advancements in nozzle technology not only contribute to compliance with emissions standards but also enhance vehicle performance, ultimately delivering better mileage. As the automotive sector continues to embrace innovation, the importance of Fuel Nozzles cannot be overstated; they are integral to achieving sustainable mobility and driving down operational costs in the long term.

Fuel nozzles are essential components in modern engines, playing a pivotal role in the efficiency and environmental impact of fuel combustion. They are designed to precisely deliver fuel into the combustion chamber, ensuring that the right amount of fuel mixes with air for optimal combustion. This precision not only enhances engine performance but also contributes to lower emissions, reducing the vehicle’s carbon footprint.

When considering fuel nozzles, it’s crucial to understand their various functions, which range from atomizing the fuel to creating an ideal mixture for combustion. A well-functioning fuel nozzle ensures that fuel is sprayed in a fine mist, allowing for better ignition and a more complete burn. This process improves overall fuel efficiency, which can save drivers money and promote cleaner air.

Tip: Regularly inspect your fuel nozzles for wear and tear to maintain their efficiency. Cleaning or replacing worn nozzles can significantly improve engine performance.

Another handy tip is to choose high-quality fuel that is compatible with your engine's design. This can help maintain the health of the fuel injection system and prevent clogging in the nozzles. Keeping your fuel system well-maintained will contribute to better fuel economy and lower emissions over time.

Precision fuel nozzles play a crucial role in enhancing engine performance and fuel efficiency. These components are engineered to deliver a finely atomized spray of fuel, which allows for optimal mixing with air in the combustion chamber. When fuel is atomized correctly, it ensures a more complete combustion process, leading to improved power output and a reduction in unburned fuel. This not only enhances the overall performance of the engine but also contributes significantly to fuel savings over time.

Moreover, the impact of precision fuel nozzles extends beyond mere efficiency; they are integral to emission control. By ensuring precise fuel delivery, these nozzles help minimize the formation of harmful emissions such as hydrocarbons and nitrogen oxides. Engines equipped with high-quality, precision-engineered nozzles operate at lower temperatures and achieve a more balanced air-fuel ratio, which are critical factors in reducing environmental impact. Consequently, investing in precision fuel nozzles is not just beneficial for performance but is also a significant step toward achieving stricter emission standards and promoting cleaner air.

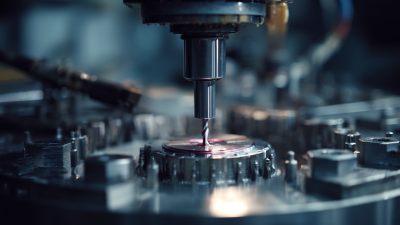

Fuel nozzle design plays a pivotal role in determining the efficiency and cleanliness of fuel combustion. Precision engineering in fuel nozzles ensures that fuel is atomized properly, allowing for optimal mixing with air. This fine atomization leads to more complete combustion, which drastically reduces the amount of unburned hydrocarbons and particulate matter released into the atmosphere. As stricter environmental standards are implemented worldwide, innovative fuel nozzle technologies are essential for meeting these requirements while maintaining engine performance.

Furthermore, the shape and size of fuel nozzles can significantly influence emission levels. Nozzles that are designed to achieve various spray patterns can enhance the distribution of fuel within the combustion chamber, thereby promoting a more uniform burn. This uniformity directly correlates with lower emission levels, particularly for nitrogen oxides (NOx) and carbon monoxide (CO). As the automotive and aviation industries push toward greener technologies, advancements in fuel nozzle design will remain critical in achieving compliance with increasingly stringent environmental regulations.

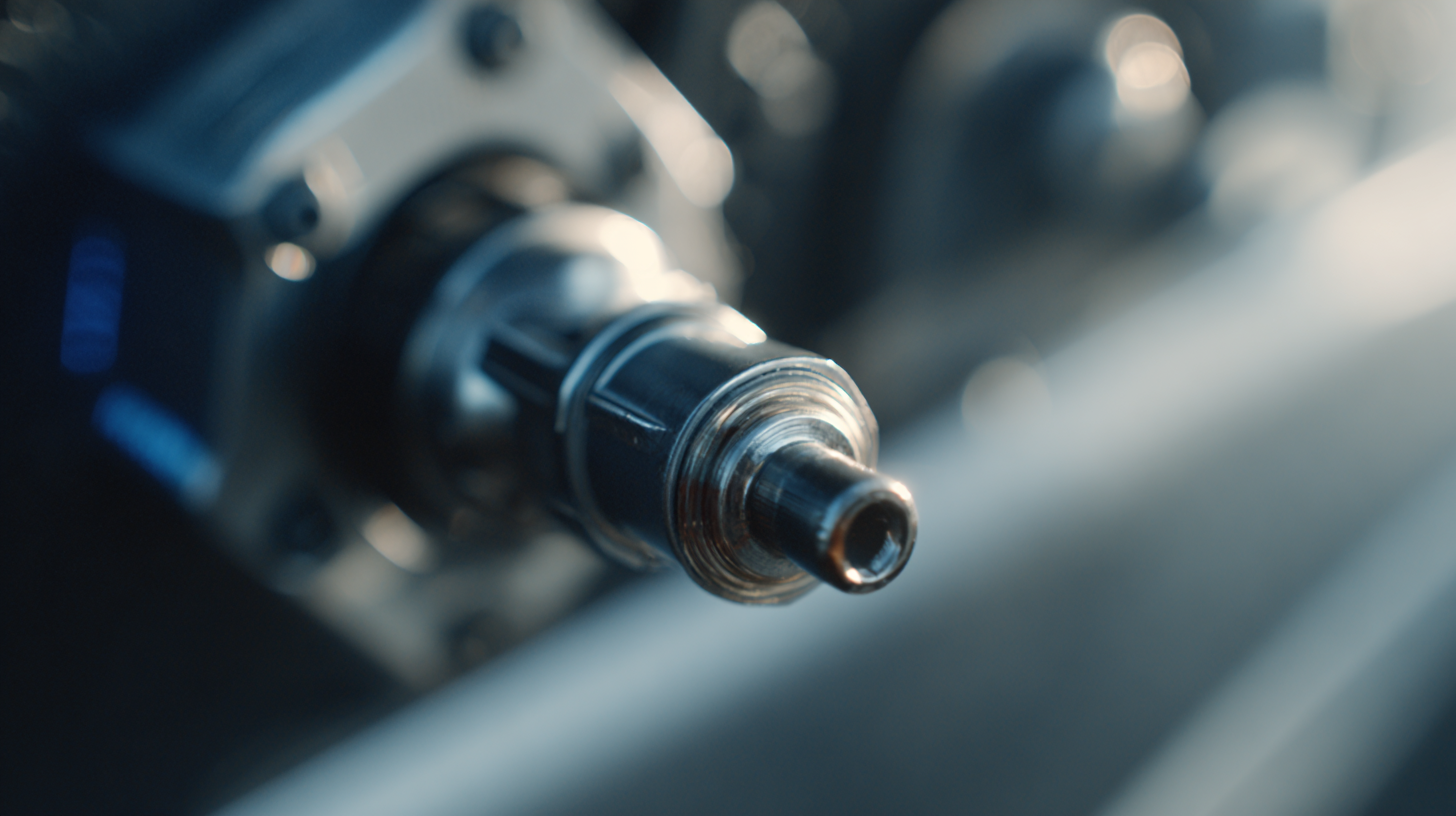

Maintaining fuel nozzles is essential for optimizing the performance of your fuel system and ensuring compliance with emission standards. Regular inspection is crucial; it allows for the early detection of wear or clogging, which can significantly impact fuel atomization. It's advisable to check for any signs of corrosion or degradation, particularly in environments with high humidity or exposure to contaminants. Keeping fuel lines clean and filter replacements timely are also essential maintenance practices that help sustain the functionality of fuel nozzles.

Additionally, conducting periodic performance tests can provide insights into the efficiency of the nozzles. If discrepancies arise in fuel consumption or emission readings, this may indicate that nozzle adjustments or replacements are necessary. Calibration of nozzles should be done according to manufacturer specifications to ensure precise fuel delivery. Implementing these maintenance tips not only enhances fuel efficiency but also contributes to overall vehicle longevity and reduced environmental impact. Regular attention to fuel nozzles ensures that they operate within optimal parameters, resulting in better performance and cleaner emissions.

Fuel nozzle technology is evolving rapidly, with a focus on precision that directly impacts fuel efficiency and emission control. As industries shift towards sustainable practices, the innovations in fuel nozzle design are critical for reducing the carbon footprint of transportation and energy systems. Enhanced fuel nozzles can optimize combustion, allowing for better fuel atomization and distribution, which ultimately leads to a cleaner burn and lower emissions. This is especially important in sectors like maritime and aviation, where meeting stringent regulatory standards is paramount.

Tips: When considering advancements in fuel nozzle technology, look for designs that incorporate advanced materials and smart technologies. These innovations not only improve durability but also enable real-time adjustments for optimal performance. Additionally, exploring the integration of electric and hybrid systems can further enhance fuel efficiency while catering to the growing demand for low-emission solutions in various industries.

The future of fuel nozzle technology is indeed promising, as companies focus on developing solutions that align with global sustainability goals. Innovations aimed at increasing precision in fuel delivery will play a vital role in achieving higher efficiency and lowering emissions across many applications. As we move towards a greener future, staying informed about these advancements is crucial for businesses and consumers alike.