When it comes to maximizing efficiency in manufacturing processes, optimizing the performance of your Tinning Machine is crucial. This specialized equipment plays a vital role in the tinning process, where metal surfaces are coated with a layer of tin for enhanced durability and corrosion resistance. However, like any machinery, a Tinning Machine can encounter performance issues that may hinder productivity and increase operational costs.

In this blog, we will delve into eight essential tips that can help you enhance the functionality of your Tinning Machine, ensuring it runs smoothly and effectively. From routine maintenance practices to proper temperature settings, these actionable insights are designed to empower you to get the most out of your tinning operations, ultimately leading to improved product quality and operational efficiency.

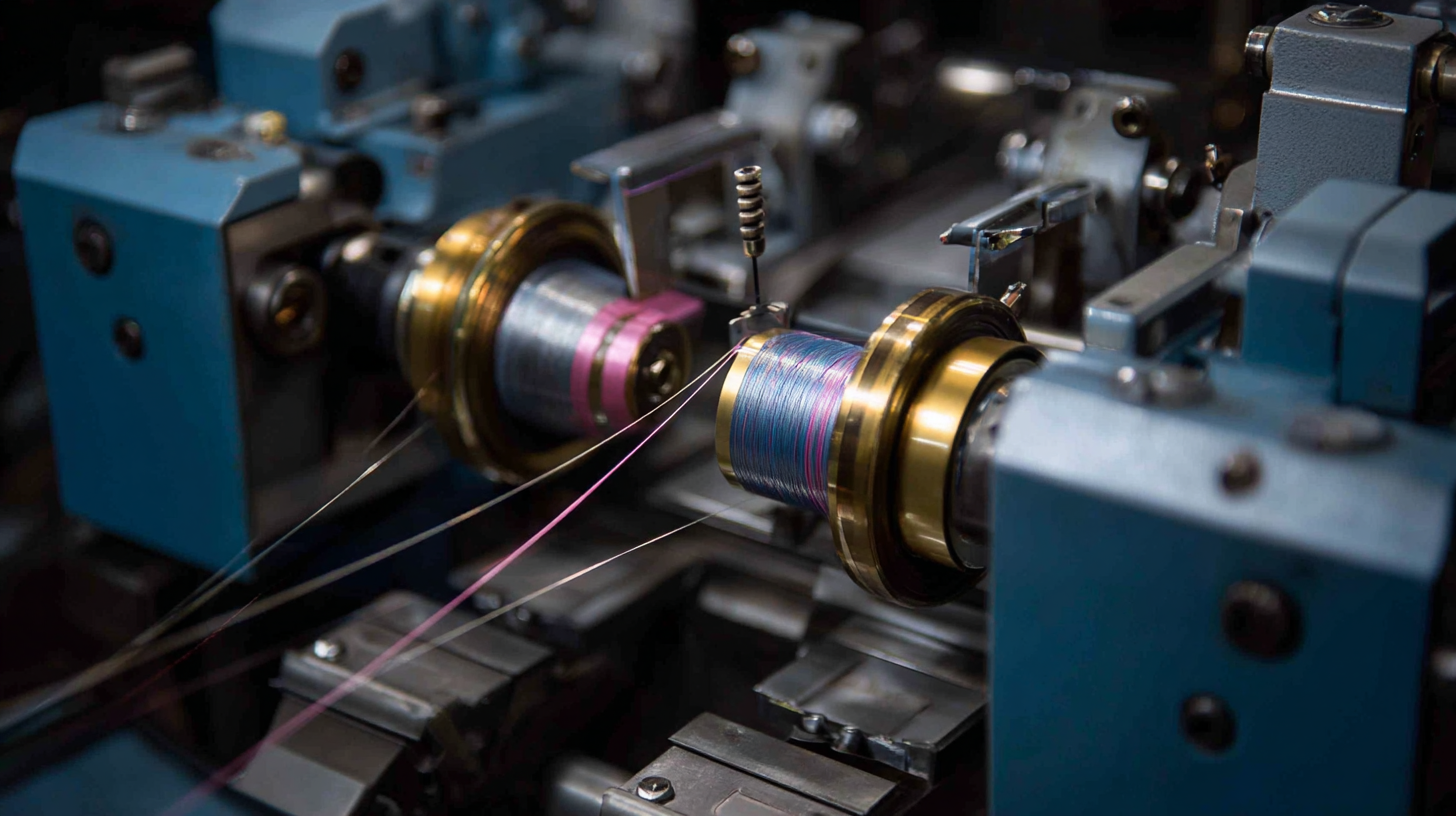

Optimizing the performance of your tinning machine is crucial for enhancing productivity and minimizing waste. Tinning machines are pivotal in electronic manufacturing, where they are used to coat solderable surfaces with tin to improve conductivity and prevent oxidation. The efficiency of these machines not only affects the quality of the finished product but also impacts the overall production process. An optimized machine can lead to quicker cycle times, decreased downtime, and higher-quality coatings, directly translating to increased profitability.

To achieve optimal performance, it’s essential to monitor and maintain the machine regularly. This includes ensuring that all components are clean and functioning correctly and that the temperature and speed settings are calibrated to suit the specific materials being used. Additionally, operator training can significantly affect machine efficiency, as knowledgeable staff can identify issues early and implement best practices. By prioritizing these optimization techniques, manufacturers can enhance their tinning processes and remain competitive in the fast-paced electronics market.

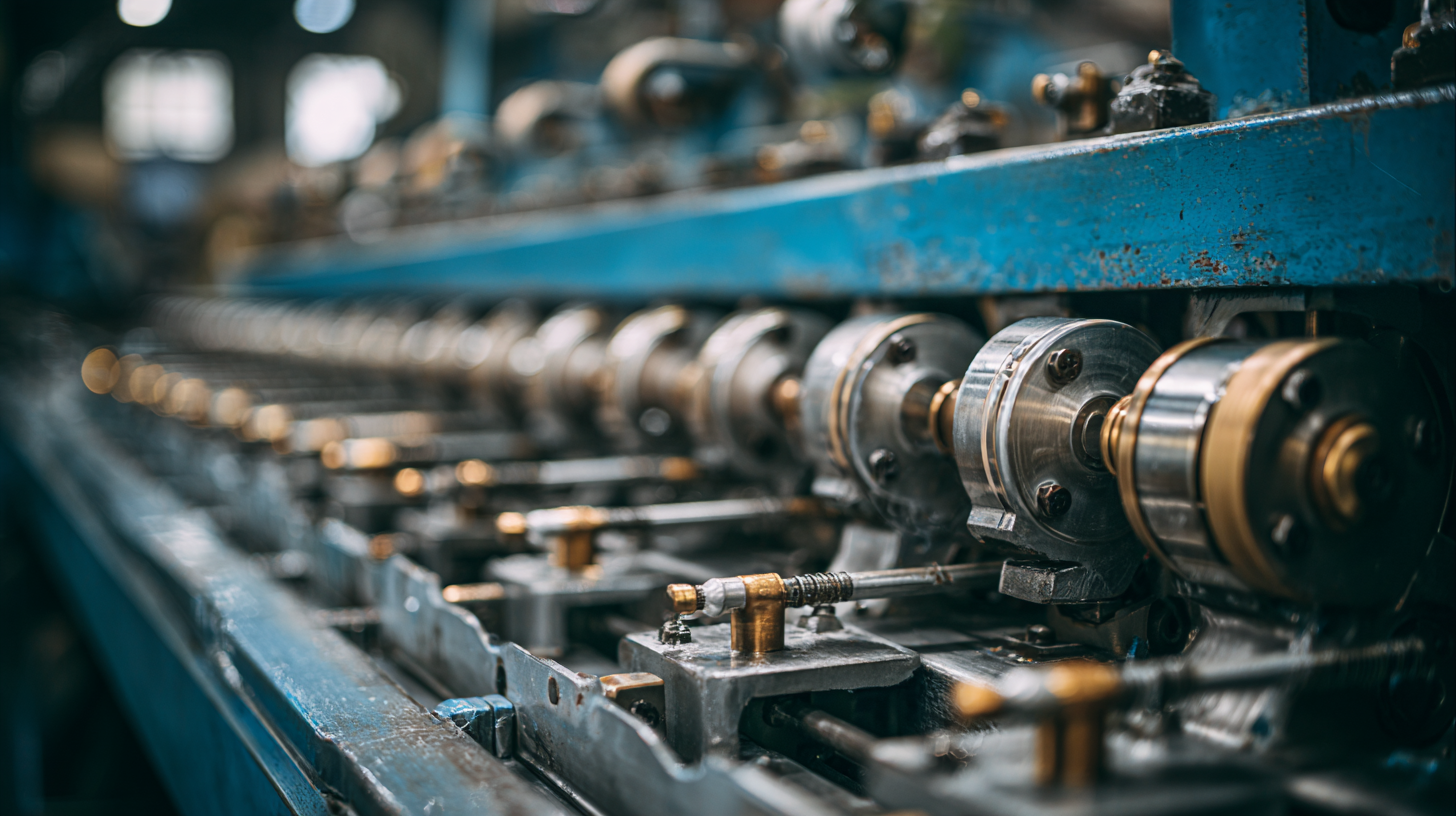

Tinning machines play a critical role in the food processing industry, particularly in preserving seafood and other products. To ensure enhanced efficiency and longevity of these machines, key maintenance practices are essential. Regular inspection and cleaning are crucial, as residual tin and contaminants can affect both the machine’s performance and the quality of the final product. According to industry reports, proper maintenance can reduce downtime by up to 30%, significantly boosting production throughput.

Moreover, monitoring the machine’s temperature and pressure settings is vital for optimal operation. Data shows that maintaining precise control over these variables can improve tin adhesion and preservation effectiveness, leading to higher product quality and lower spoilage rates. With global seafood exports being vulnerable to external economic factors, such as trade tariffs, optimizing performance through diligent maintenance could be a game changer for producers. By prioritizing these practices, tinning machine operators can not only enhance their efficiency but also better position themselves in a competitive marketplace, ultimately benefiting the entire supply chain.

| Tip No. | Maintenance Practice | Frequency | Impact on Efficiency |

|---|---|---|---|

| 1 | Regular Lubrication | Weekly | Reduces wear and friction |

| 2 | Cleaning Nozzles | Daily | Ensures even coating |

| 3 | Check Temperature Settings | Weekly | Optimizes solder adhesion |

| 4 | Inspect Electrical Connections | Monthly | Prevents power interruptions |

| 5 | Verify Material Quality | Daily | Ensures best results |

| 6 | Adjust Speed Settings | As needed | Maintains quality output |

| 7 | Calibration of Sensors | Quarterly | Enhances precision |

| 8 | Training for Operators | Annually | Improves operational skills |

Optimizing the performance of your tinning machine is crucial for achieving high-quality results in your production process. A common issue affecting tinning machine performance is improper temperature control. Maintaining the right temperature is essential for ensuring that the tin adheres properly to the surfaces. Regularly calibrating your temperature sensors and conducting routine maintenance can help mitigate this problem.

Another factor that can negatively impact performance is equipment wear and tear. Over time, parts such as nozzles and platens can degrade, leading to inconsistent tin application. To combat this, ensure you implement a regular inspection schedule where worn components are replaced promptly. Moreover, utilizing high-quality tin materials can enhance the overall performance of your machine, reducing issues related to sputtering or insufficient coating.

Finally, operator training plays a pivotal role in maximizing your tinning machine's efficiency. Ensuring that your team is well-versed in machine settings, troubleshooting common issues, and carrying out maintenance will lead to smoother operations and reduced downtime. By addressing these common challenges, you'll be on your way to optimizing your tinning machine's performance effectively.

Achieving optimal performance with your tinning machine hinges significantly on fine-tuning its settings. Start by focusing on temperature adjustments. The soldering temperature should be calibrated according to the specific materials you are working with. Too high a temperature can lead to oxidation, while too low might not form reliable solder joints. Regularly monitor and adjust the temperature settings to maintain a consistent quality of tinning.

Another critical factor is the speed of the tinning operation. Slower speeds allow for better coating and adherence, while higher speeds can compromise the quality of the tin. Experiment with different speeds to find the sweet spot that maximizes efficiency without sacrificing the integrity of the wash. Additionally, ensure that the flux used in the process is compatible with the materials. Proper flux application enhances the flow and bonding of the solder, contributing to stronger, more reliable connections. By meticulously adjusting these settings, you will enhance the overall performance of your tinning machine and achieve superior results.

In the realm of tinning machines, the quality of materials used directly impacts productivity and performance. A 2022 industry report by the International Tinning Association (ITA) noted that manufacturers who prioritized high-grade tin and substrate materials observed a productivity increase of up to 30% compared to those using subpar alternatives. This is critical in a market where precision and efficiency are paramount, as inferior materials can lead to increased defects and downtime, ultimately affecting overall output.

Selecting the right alloy composition is also crucial; according to a recent study published in the Journal of Materials Processing, the use of advanced tin alloys can enhance adhesion and reduce corrosion significantly. The research indicated that refinements in material science led to a reduction in corrosion rates by approximately 20%, enabling longer operational life for tinning machines while maintaining efficiency. Thus, investing in quality materials is not merely a matter of cost—it’s about ensuring reliability and optimizing productivity in the competitive landscape of the tinning industry.