As the global demand for advanced technology continues to surge, the thin film coating industry has witnessed remarkable growth, projected to reach a valuation of over $17 billion by 2027 according to recent market analyses. Thin Film Coating Machines have become indispensable in various sectors, including electronics, optics, and healthcare, where their precision and versatility significantly enhance product performance and durability. With a myriad of options available in the market, selecting the right machine can be a daunting task for businesses aiming to optimize their manufacturing processes. Understanding the essential features and capabilities of these machines is crucial for making an informed investment that aligns with operational needs and budget constraints. In this blog, we will explore seven essential tips to help you choose the perfect Thin Film Coating Machine for your business, ensuring you stay competitive in this rapidly evolving industry.

When selecting the perfect thin film coating machine for your business, several key factors should be considered to ensure you meet your specific needs. The market for transparent conductive films, which utilize materials like indium tin oxide (ITO), silver nanowires, carbon nanotubes, and metal meshes, has been expanding significantly. According to industry analysis, this sector is driven by the increasing demand in applications such as consumer electronics and automation. For instance, the global market for ITO is projected to grow, reflecting an increasing trend towards advanced materials that facilitate the development of innovative electronic devices.

Furthermore, the desktop UV curing machine market is also witnessing substantial growth. Valued at approximately $6.8 million in 2022, it is expected to reach around $11.5 million by 2030, with a compound annual growth rate (CAGR) of 7.0% from 2024 to 2030. This growth is indicative of the rising need for efficient and high-quality curing processes in various industries. As a business seeking to invest in thin film coating technology, understanding these trends and data will help position your operations for success in an increasingly competitive market.

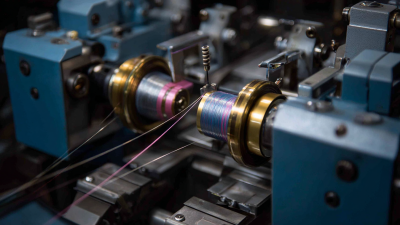

When selecting the perfect thin film coating machine for your business, it's crucial to understand the various thin film coating technologies available and their specific applications. Among the traditional methods, chemical vapor deposition (CVD) and thermal evaporation are widely used due to their effectiveness in producing high-quality coatings. Recent advancements in techniques like initiated chemical vapor deposition (iCVD) have shown great promise, especially for applications requiring flexible membranes in fields such as water treatment, battery manufacturing, and drug delivery.

Additionally, the emerging field of anti-corrosion thin films has underscored the importance of selecting the right coating technology to enhance the durability of materials. With numerous options available, businesses can discover specialized coatings that not only provide protection but also improve the material's overall performance. Research into surface-confined enzymatic methods for scalable thin film generation highlights the significant potential for customization in application, which can cater to specific needs across various industries. By staying informed about innovative developments and the latest trends in thin film coating technologies, businesses can make well-informed choices that align with their operational demands.

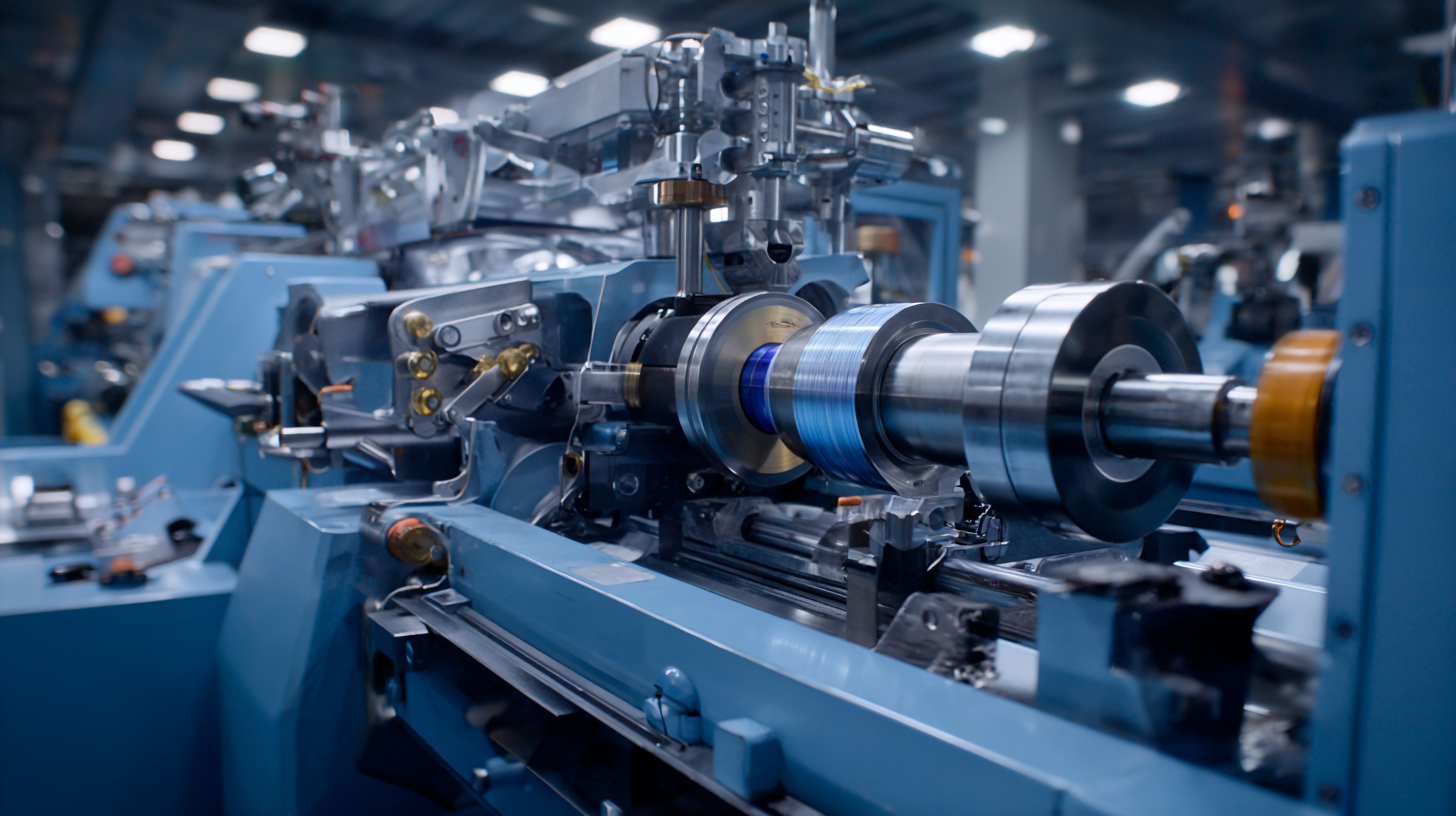

When selecting a thin film coating machine, understanding the production capacity is crucial for aligning machine specifications with your business volume. The capacity utilization rate, which measures the percentage of potential output being achieved, is a key indicator in this process. According to industry reports, maximizing capacity utilization can significantly reduce production slack, leading to enhanced efficiency and reduced operational costs. For example, businesses operating at 85% capacity utilization or higher often see a more streamlined workflow and lower per-unit production costs, allowing them to remain competitive in a challenging market.

Incorporating advanced manufacturing techniques, such as machine learning for root cause analysis, can also play a pivotal role in optimizing production. This systematic approach helps identify defects early in the manufacturing process, thereby minimizing waste and improving the overall efficiency of operations. Companies that invest in these technologies can achieve lower defect rates, which is crucial in highly competitive sectors such as electronics and automotive parts manufacturing. For businesses aiming for zero-defect manufacturing, aligning the capabilities of thin film coating machines with these industry best practices ensures not only production efficiency but also product quality across their offerings.

When selecting the perfect thin film coating machine for your business, understanding the cost-effectiveness is crucial. Initial investments can be substantial, but evaluating these costs in terms of long-term savings can lead to better economic outcomes. Recent studies highlight the importance of employing comprehensive cost analyses, such as Time-Driven Activity-Based Costing, to assess the financial benefits that advanced systems can offer over time. Businesses often find that a higher upfront cost can result in significant savings through increased efficiency and reduced operational expenditures.

Furthermore, the economic performance of technology-driven solutions showcases an undeniable trend: investments in state-of-the-art equipment tend to pay off in various ways. For example, companies that integrate advanced thin film coating technologies are likely to see improved productivity and reduced waste, mirroring findings in other sectors like sustainable building upgrades and digital health interventions. By prioritizing equipment that not only fits within budget constraints but also aligns with long-term sustainability goals, businesses can maximize their return on investment (ROI) while contributing to broader environmental initiatives.

When selecting a thin film coating machine for your business, the importance of vendor support and maintenance cannot be overstated. A high-quality machine is an investment, but its longevity and operational efficiency greatly depend on the support offered by the vendor. Prospective buyers should prioritize manufacturers who provide comprehensive training for their staff, ensuring they are well-equipped to operate and maintain the system effectively. This training is vital not only for maximizing production efficiency but also for preventing costly downtime caused by misunderstanding or misusing the equipment.

Moreover, ongoing maintenance and support from the vendor can greatly enhance the machine's performance and reliability. A strong vendor partnership means access to timely support, essential spare parts, and expert guidance when challenges arise. Look for vendors who offer flexible service agreements that include regular check-ups and tune-ups, which can significantly extend the life of your machine. Choosing a vendor that is committed to customer support not only helps in troubleshooting issues swiftly but also contributes to building a long-term, productive relationship, ensuring your business thrives in a competitive market.