The maintenance of tinning machines is crucial for sustaining optimal performance and productivity in the manufacturing sector, especially in electronics and automotive industries where precision and quality are paramount. According to a report by MarketsandMarkets, the global tin market is expected to reach a value of $8.6 billion by 2025, with a significant demand surge linked to improved manufacturing processes and efficient machinery. Regular maintenance of tinning machines not only enhances operational efficiency but also extends the lifespan of this critical equipment; studies show that well-maintained machines can experience up to a 30% reduction in downtime. This guide aims to provide actionable insights on how to effectively maintain your tinning machine, ensuring that you achieve optimal performance and contribute to the overall success of your production line.

Regular maintenance of tinning machines is crucial for ensuring optimal performance and longevity. Just like manual soldering skills, where proper training enhances proficiency, the upkeep of machinery requires a knowledgeable approach. Neglecting routine maintenance can lead to decreased functionality, increased downtime, and ultimately higher operational costs. By sticking to a scheduled maintenance plan, operators can identify potential issues early, ensuring that the machines run smoothly and efficiently.

In the context of tinning machines, regular checks on key components, including heating elements and conveyor systems, can prevent unexpected failures. Moreover, keeping the equipment clean and free from debris is essential to maintain the quality of the tinning process. This not only improves the machine's reliability but also enhances the overall quality of the finished product, leading to better outcomes in wire assembly and soldering applications. Effective maintenance practices, therefore, play a significant role in maximizing productivity and reducing waste in the tinning operation.

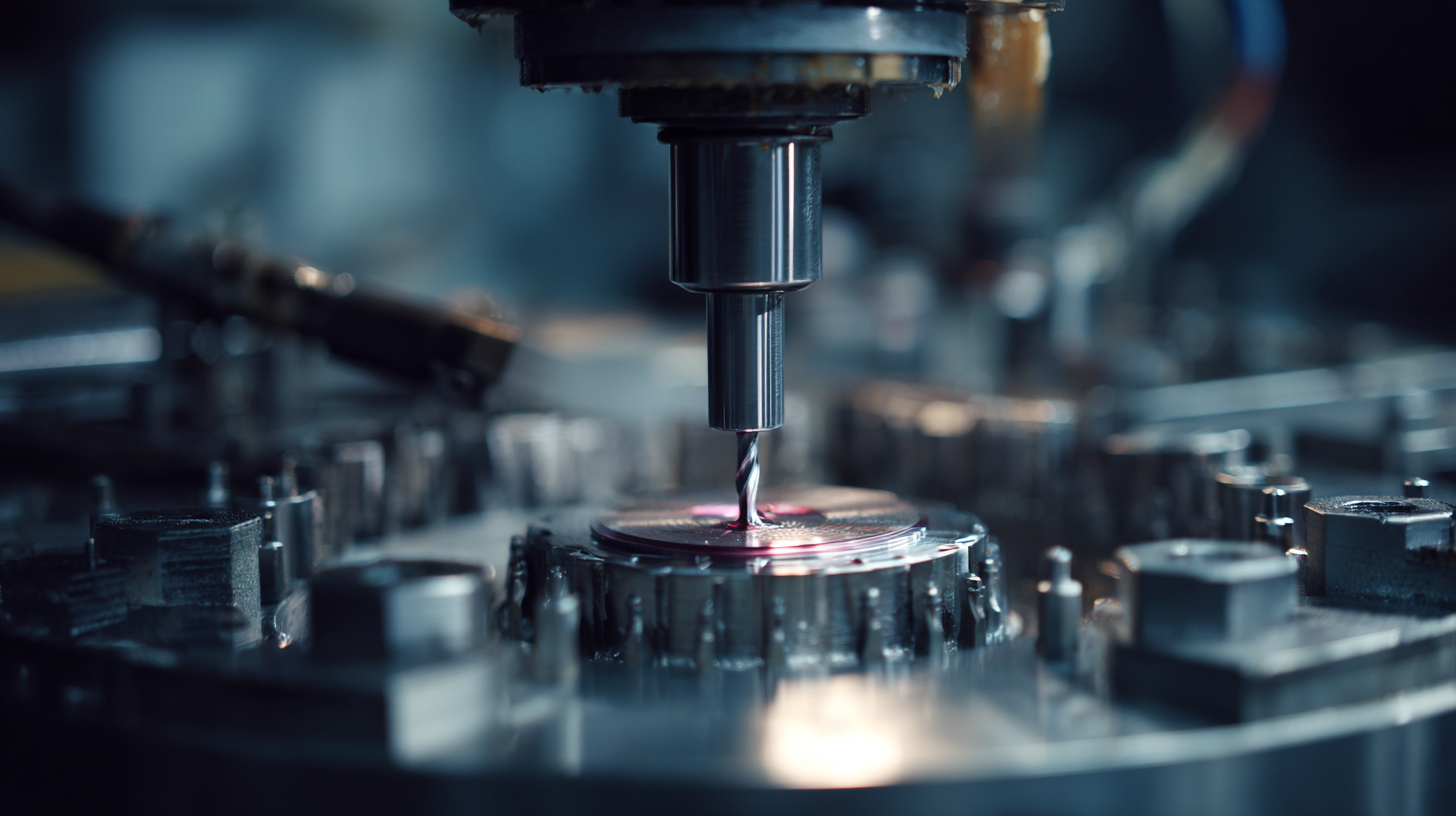

Maintaining a tinning machine requires careful attention to several key components that significantly influence its performance. Firstly, the heating elements should be regularly inspected for even distribution of heat. Uneven heating can lead to poor tinning quality and increased waste, so ensuring that these elements are functioning properly is crucial. Additionally, monitoring the temperature control systems will help maintain optimal operational settings, preventing overheating or underheating, both of which can negatively impact the tinning process.

Another critical aspect to consider is the cleanliness of the machine, particularly the soldering area. Residue build-up can affect the flow of solder and result in inconsistent coating. Regular cleaning schedules should be established to remove oxidation and debris. Furthermore, the mechanical parts, such as conveyor belts and rollers, should be examined for wear and tear. Ensuring these components are in good condition guarantees smooth operation and efficiency, reducing downtime and extending the life of the machine. By focusing on these essential components, one can effectively enhance the performance and longevity of the tinning machine.

Tinning machines play a crucial role in various manufacturing processes, but they are not without their challenges. Common issues include overheating, inconsistent tin coverage, and mechanical failures. Overheating can lead to premature wear and reduced efficiency, while inconsistent tin coverage may result from improper temperature control or faulty conveyor systems. Regular maintenance and timely troubleshooting are essential to address these problems before they escalate.

Tinning machines play a crucial role in various manufacturing processes, but they are not without their challenges. Common issues include overheating, inconsistent tin coverage, and mechanical failures. Overheating can lead to premature wear and reduced efficiency, while inconsistent tin coverage may result from improper temperature control or faulty conveyor systems. Regular maintenance and timely troubleshooting are essential to address these problems before they escalate.

Tips for Maintenance:

Cleaning and lubrication are critical for the optimal performance of tinning machines, which play a vital role in various industrial applications, particularly in electronics and component manufacturing. According to the IPC standard, regular maintenance can improve equipment efficiency by up to 30%. To keep your tinning machine operating at peak performance, establish a routine cleaning schedule that removes flux residues and other contaminants. This can be achieved with non-corrosive cleaning agents and brushes designed specifically for delicate components. Daily inspections should include checking the cleanliness of critical parts, ensuring that the surfaces are free from buildup.

Lubrication is equally essential, as it reduces wear and tear on moving parts, which can prevent costly downtime. A report from Machinery Maintenance indicates that proper lubrication can extend the lifespan of machinery by 20-50%. Use the manufacturer-recommended lubricants and apply them according to the prescribed intervals. Consistent lubrication not only enhances the smooth operation of tinning machines but also ensures that they're running under optimal temperatures, minimizing the risk of overheating. By adhering to these best practices, operators can safeguard their investments and ensure the long-term reliability of their tinning processes.

Effectively scheduling and documenting maintenance activities for tinning machines is crucial for ensuring their optimal performance and longevity. A well-structured maintenance schedule should be developed based on the manufacturer's recommendations and the specific operational demands of the machine. Regularly scheduled activities, such as cleaning, lubrication, and part inspections, help prevent unexpected breakdowns and maintain consistent production quality. It is beneficial to create a timetable that outlines these tasks on a daily, weekly, or monthly basis, depending on the frequency of machine use and production levels.

Documentation of maintenance activities serves as a vital tool for tracking the machine's performance and understanding its maintenance history. Each completed task should be recorded, noting the date, performed actions, and any observations or issues discovered during the maintenance process. This information can provide insights into potential recurring problems and assist in making informed decisions for future upgrades or modifications. Furthermore, a thorough maintenance log helps ensure compliance with industry standards and safety regulations, while also supporting training initiatives for new operators who may benefit from understanding the machine's maintenance needs.

| Maintenance Activity | Frequency | Responsible Person | Last Completed | Next Due | Notes |

|---|---|---|---|---|---|

| Clean Tinning Head | Weekly | John Doe | 2023-09-20 | 2023-09-27 | Ensure no residue remains |

| Inspect Electrical Connections | Monthly | Jane Smith | 2023-08-15 | 2023-09-15 | Check for wear and corrosion |

| Lubricate Moving Parts | Quarterly | Alex Johnson | 2023-07-05 | 2023-10-05 | Use manufacturer-approved lubricant |

| Calibrate Temperature Sensors | Bi-Annually | Emily Davis | 2023-05-10 | 2023-11-10 | Ensure accurate readings |

| Replace Worn Components | As Needed | Chris Lee | 2023-09-10 | N/A | Monitor for performance decline |