In the manufacturing sector, the selection of the right Spray Coating Equipment is crucial for enhancing productivity and ensuring quality finishes. According to a report by Research and Markets, the global market for spray coating equipment was valued at approximately $16 billion in 2021 and is expected to grow significantly with a projected CAGR of over 5% through 2026. This growth is driven by increasing demand in industries such as automotive, aerospace, and consumer goods, where efficient coating technologies can reduce waste and ensure superior adhesion.

Additionally, the rise of automation and advanced technologies, such as electrostatic spray systems, has transformed the coating process, making it more versatile and effective. Choosing the best equipment not only improves operational efficiency but also contributes to sustainability efforts by minimizing overspray and resource consumption. Therefore, understanding your specific industrial needs and the features of various spray coating options is essential for making an informed investment.

When selecting the best spray coating equipment for your industrial needs, it's crucial to first understand your specific coating requirements. Different industries, from automotive to aerospace, have varying standards and performance criteria that the coating must meet. According to the "Global Coating Market Trends" report published by Coatings World, the demand for high-performance coatings is projected to reach $200 billion by 2025, driven by stringent regulatory standards and improved product durability. This growth implies that companies need to invest in equipment tailored to handle advanced materials while ensuring compliance with environmental regulations.

Acknowledging factors such as viscosity, curing time, and surface compatibility is essential. For instance, manufacturing facilities that specialize in aerospace components often require equipment capable of applying coatings that can withstand extreme temperatures and corrosion. The "2022 Industrial Coatings Report" by the National Paint and Coatings Association emphasizes that selecting the right application method—be it airless spray, electrostatic spray, or conventional spraying—can significantly impact the efficiency and quality of the coating process. Hence, evaluating your specific operational needs alongside these industry insights can guide you in choosing the most suitable spray coating equipment.

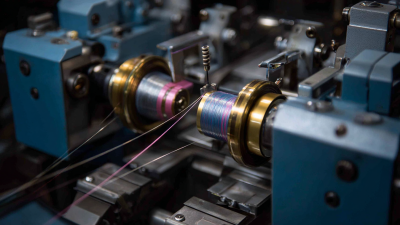

When evaluating different types of spray coating equipment, it's essential to understand the specific requirements of your industrial applications. The primary types of spray coating equipment include airless, air-assisted airless, and conventional spray systems.

Airless systems are favored for their efficiency and ability to deliver thicker coatings without the need for compressed air. This type is ideal for large surfaces and projects requiring high-speed application.

On the other hand, air-assisted airless systems combine the benefits of airless technology with a fine spray pattern. They are particularly effective for achieving a smooth finish on intricate surfaces, making them suitable for detailed work.

Conventional spray systems, while less efficient than their airless counterparts, may still be preferred for specific applications, such as applying lighter coatings or when the environment demands a lower spray pressure. Each type of equipment has its own set of advantages and disadvantages, so careful consideration of your production needs, project size, and desired finish is crucial in making an informed choice.

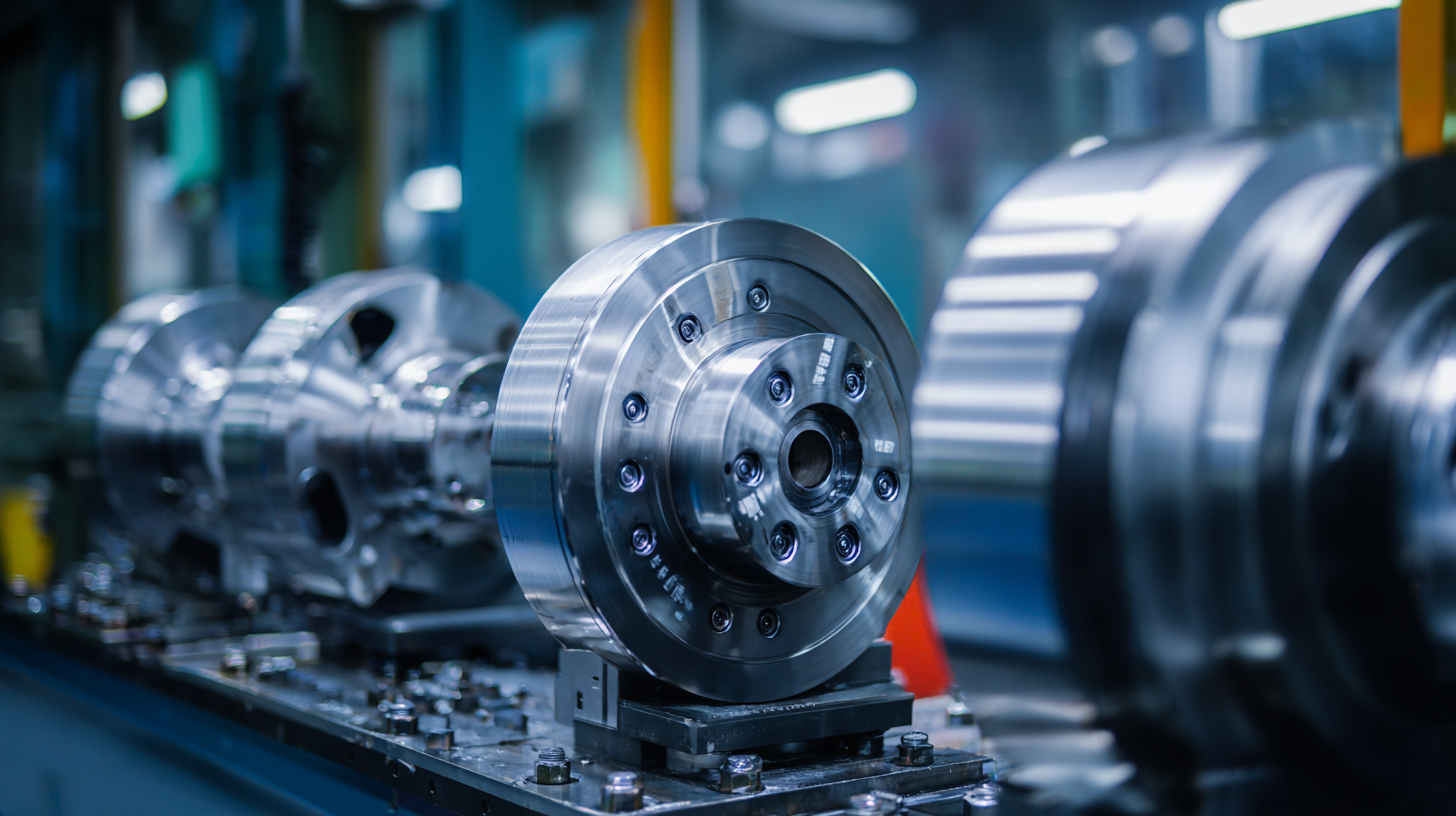

When selecting the best spray coating equipment for industrial applications, assessing the efficiency and productivity of coating systems is crucial. According to a report by MarketsandMarkets, the global spray coating equipment market is projected to reach $2.3 billion by 2025, driven by advances in technology that enhance coating precision and reduce waste. High-efficiency coating systems minimize overspray and improve material utilization, which can lead to significant cost savings. Systems with electrostatic spray technology can achieve transfer efficiencies of up to 90%, compared to conventional systems that often max out around 40%.

In addition to material efficiency, the productivity of the coating process directly impacts overall manufacturing throughput. A study by the American Coatings Association highlights that modern coating systems can reduce application time by as much as 30% when using automated solutions. By investing in upgraded spray application equipment that incorporates features like programmable controls and advanced nozzles, industries can not only streamline their operations but also ensure a consistent and high-quality finish. Improved productivity often translates to shorter lead times and greater customer satisfaction, positioning companies to compete effectively in the marketplace.

When selecting spray coating equipment for industrial use, maintenance and support are critical factors that should not be overlooked. The longevity and effectiveness of your equipment heavily depend on the manufacturer's commitment to service and availability of parts. A good indicator of reliable support is the reputation of the manufacturer. Companies with robust customer service histories often provide quicker responses to maintenance needs and ensure that spare parts are readily accessible. This can greatly reduce downtime and keep production schedules on track.

Furthermore, understanding the maintenance requirements of your chosen equipment is essential for optimal performance. Look for machines that offer easy maintenance access and come with clear instructions for routine care. Additionally, consider training programs or resources that the manufacturer may offer, which can help in empowering your team to handle minor issues without the need for outside help. This proactive approach not only diminishes the chances of equipment failure but also fosters a more efficient working environment, ultimately contributing to better overall productivity.

When considering the best spray coating equipment for industrial needs, budgeting plays a crucial role. It’s essential to not only account for the initial purchase price but also to evaluate the long-term costs associated with maintenance, operation, and compliance. For instance, while high-quality spray systems may have a higher upfront cost, they often provide faster application and better coverage, leading to increased efficiency over time. This can translate into lower labor costs and reduced downtime, making them a worthwhile investment.

Moreover, the evolving landscape of spray coating technology includes advancements such as improved air movement systems and LED lighting to enhance drying times. These innovations can significantly impact operational costs and efficiency, demonstrating the importance of selecting the right equipment. Businesses should also consider factors such as the durability of coatings and potential savings from reduced re-coating needs due to enhanced corrosion protection. By thoroughly assessing both the purchase price and long-term operational implications, companies can make informed decisions that align with their financial objectives and operational requirements.