In today's ever-evolving industrial landscape, the significance of efficient metal coating processes cannot be overstated, particularly as industries push for enhanced durability and corrosion resistance.

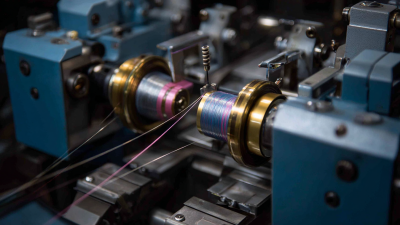

Tinning machines have emerged as pivotal tools in this arena, streamlining the tinning process essential for various applications, from electronics to automotive components.

According to a recent report by MarketsandMarkets, the global metal coating market is projected to reach $32 billion by 2025, driven by increasing demand for protective coatings that extend product lifespan and performance.

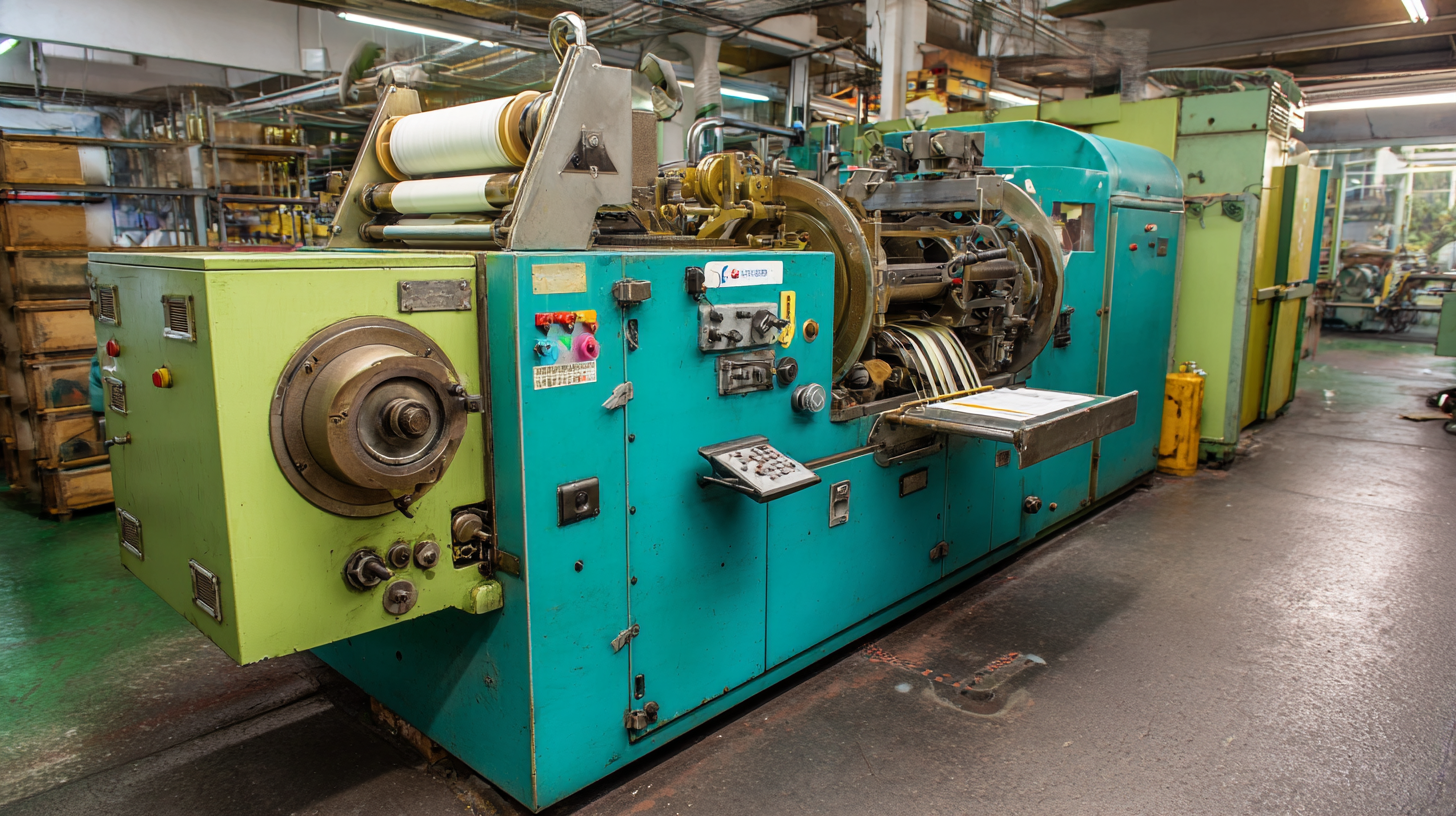

The adoption of advanced tinning machines enhances consistency and quality in coating processes, thereby reducing waste and improving operational efficiency.

As industries increasingly prioritize sustainable practices, leveraging cutting-edge tinning machines is not just a trend but a necessary step toward meeting stringent quality standards and achieving long-term cost savings.

Tinning machines have emerged as pivotal tools in this arena, streamlining the tinning process essential for various applications, from electronics to automotive components.

According to a recent report by MarketsandMarkets, the global metal coating market is projected to reach $32 billion by 2025, driven by increasing demand for protective coatings that extend product lifespan and performance.

The adoption of advanced tinning machines enhances consistency and quality in coating processes, thereby reducing waste and improving operational efficiency.

As industries increasingly prioritize sustainable practices, leveraging cutting-edge tinning machines is not just a trend but a necessary step toward meeting stringent quality standards and achieving long-term cost savings.

The economic impact of tinning machines on metal coating efficiency in manufacturing cannot be overstated. Tinning, a process that involves applying a thin layer of tin onto copper or other metals, significantly enhances the corrosion resistance and solderability of the coated surface. As companies increasingly prioritize durability and performance in their products, the introduction of advanced tinning machines streamlines the coating process, reducing both labor costs and material wastage. This efficiency not only lowers operational expenses but also increases the output per unit time.

Moreover, the adoption of modern tinning machines positively influences production cycles. With automated systems capable of achieving consistent and uniform coating, manufacturers can expect a decrease in quality control issues and a reduction in rework rates. This improvement in coating precision translates to lower production downtime and contributes to higher overall productivity. Consequently, manufacturers who invest in these advanced tinning technologies can gain a competitive edge in the market, ultimately leading to increased profitability and sustained growth in the metalworking industry.

Tinning machines play a pivotal role in modern metal coating processes, bringing substantial benefits in terms of material efficiency and sustainability. According to a recent report by the International Journal of Metal Coating Technologies, the adoption of advanced tinning technology can reduce metal waste by up to 30%. This reduction is crucial in industries where raw material costs are rising, and environmental concerns are paramount. By optimizing the coating process, businesses not only save on costs but also contribute to a more sustainable production cycle.

Implementing tinning machines also allows manufacturers to minimize their carbon footprint. Data from the Global Sustainability Report 2023 indicates that companies utilizing efficient coating technologies can lower their energy consumption by as much as 25%. This efficiency not only supports environmental sustainability but also enhances competitiveness in the marketplace.

Tips: When considering the integration of tinning machines, companies should assess their existing processes to identify areas where waste reduction is achievable. Additionally, investing in training for staff on the latest tinning technologies can enhance operational efficiency, leading to further improvements in sustainability. Continuous monitoring of material usage can also help track progress and optimize performance in real-time.

Advanced technologies in tinning machines are transforming metal coating processes across various industries. Innovations such as precision temperature control and advanced conveyor systems enable cleaner, more efficient coatings that enhance product durability. According to a report by Grand View Research, the global metallic coatings market is expected to reach USD 33.5 billion by 2027, growing at a CAGR of 5.9%. This growth is fueled by the increasing demand for protective coatings that improve the lifespan and performance of metal products.

The emergence of smart tinning machines equipped with IoT capabilities allows for real-time monitoring and data analysis, ensuring quality assurance throughout the production process. These systems not only minimize material waste but also streamline operations by reducing downtime. As noted in a study by MarketsandMarkets, the industrial automation market is projected to grow from USD 175.8 billion in 2021 to USD 265.5 billion by 2026, indicating a significant trend towards automation in manufacturing processes, including tinning.

Tip: To maximize the efficiency of your tinning machine, regularly maintain and calibrate the equipment to ensure optimal performance. Consider investing in training for your operators to familiarize them with advanced features that can improve productivity.

Tip: Stay updated on the latest innovations in metal coating technologies and explore partnerships with suppliers who offer cutting-edge solutions that align with your business needs. This proactive approach can give your operations a competitive edge.

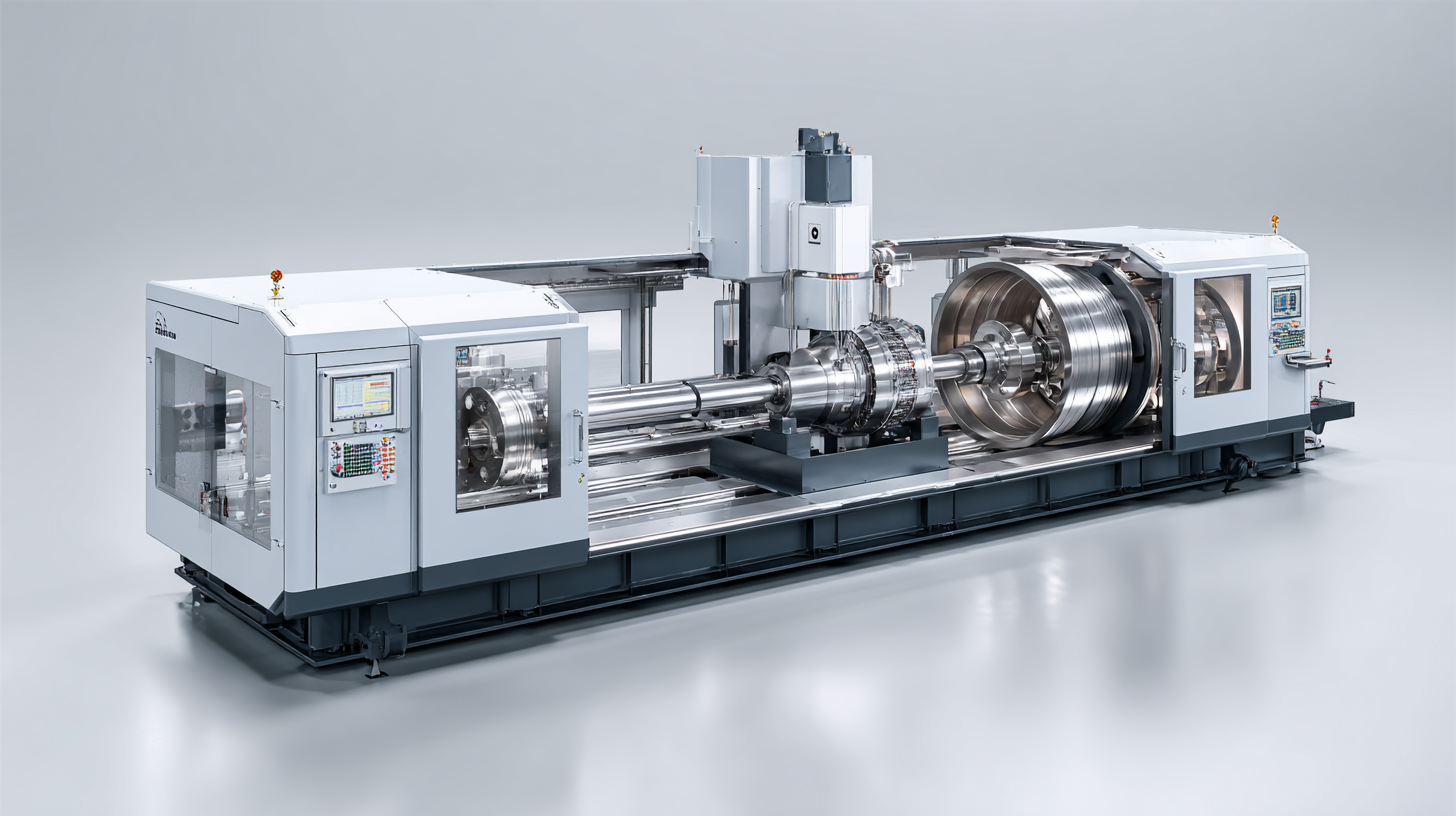

The integration of tinning machines in metal coating processes has revolutionized various industries, providing a significant edge in performance metrics. Recent statistical insights reveal that the efficiency of tinning machines can lead to a reduction in production time by as much as 30%, improving throughput and allowing for higher volumes of coated products. This is critical for industries that rely on rapid turnaround times, such as electronics and automotive manufacturing. Furthermore, enhanced adhesion properties resulting from advanced tinning techniques contribute to the longevity and durability of the coated materials, reducing the need for frequent replacements.

**Tips for Maximizing Tinning Machine Efficiency:**

1. Regular maintenance checks and adjustments to the machine's settings can prevent downtime and ensure optimal performance.

2. Investing in training for operators can help in understanding the nuances of the machine, leading to better handling and efficiency.

3. Keep track of performance metrics, such as downtime and output quality, to identify areas for continuous improvement.

By leveraging these insights and tips, industries can unlock the full potential of tinning machines, ensuring effective metal coating processes that meet modern manufacturing demands.

The comparison between manual and automated tinning processes reveals significant implications for the industry, particularly in terms of efficiency and consistency. Manual tinning, while valuable for intricate tasks, can often lead to variations in quality and increased labor costs. In contrast, automated tinning machines streamline the process, enhancing precision and allowing for higher volumes of production. This is crucial in sectors that demand reliability, such as electronics and automotive manufacturing, where even minor defects can result in substantial financial losses and safety risks.

Moreover, the benefits of utilizing automated tinning machines extend beyond just production efficiency. Properly executed tinning significantly improves the operational characteristics of the tin-coated materials, including their temperature resilience and resistance to environmental factors like moisture. This leads to not only improved product performance but also extends the lifespan of components, thereby optimizing supply chain processes.

Ultimately, the decision between manual and automated tinning will largely depend on the specific requirements of a manufacturing operation, with many realizing that investing in automated solutions offers a competitive edge in today’s fast-paced industrial landscape.